by Gordon Post | Jul 11, 2024 | Uncategorized

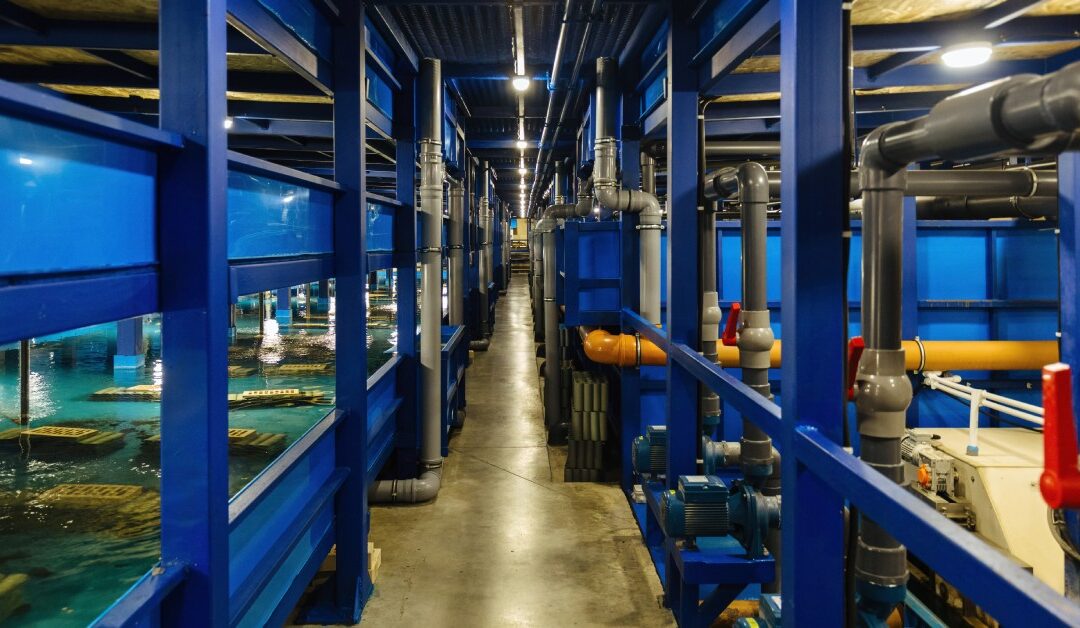

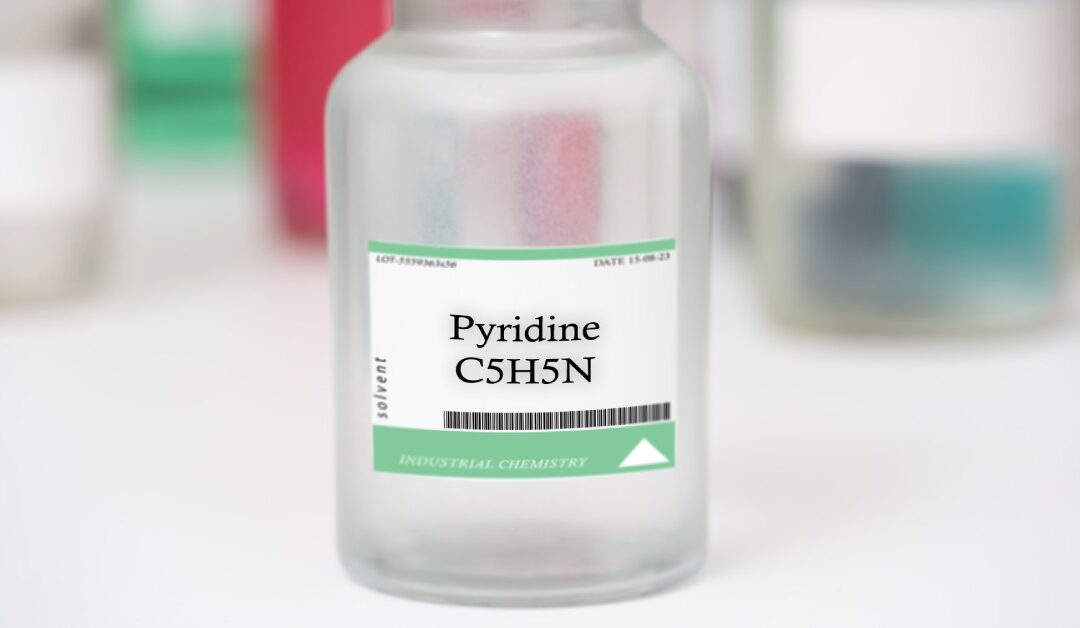

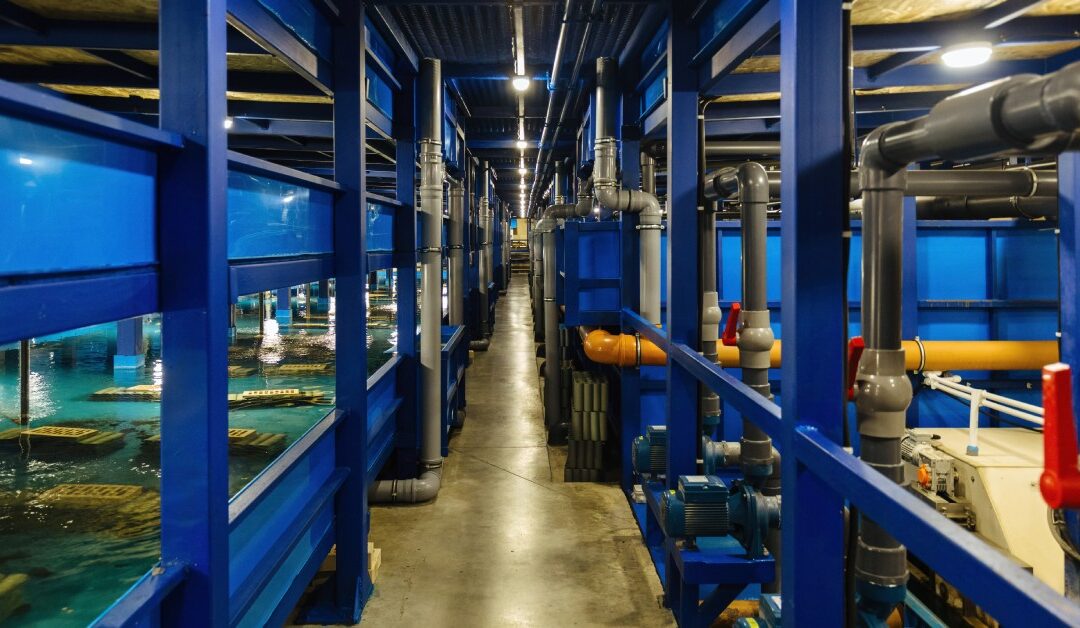

Commercial aquariums rely on a precise balance of chemicals to maintain the health and well-being of their aquatic inhabitants. Understanding these chemicals is essential for marine biologists and aquarium managers to create a successful and thriving aquarium...

by Gordon Post | Jun 24, 2024 | Uncategorized

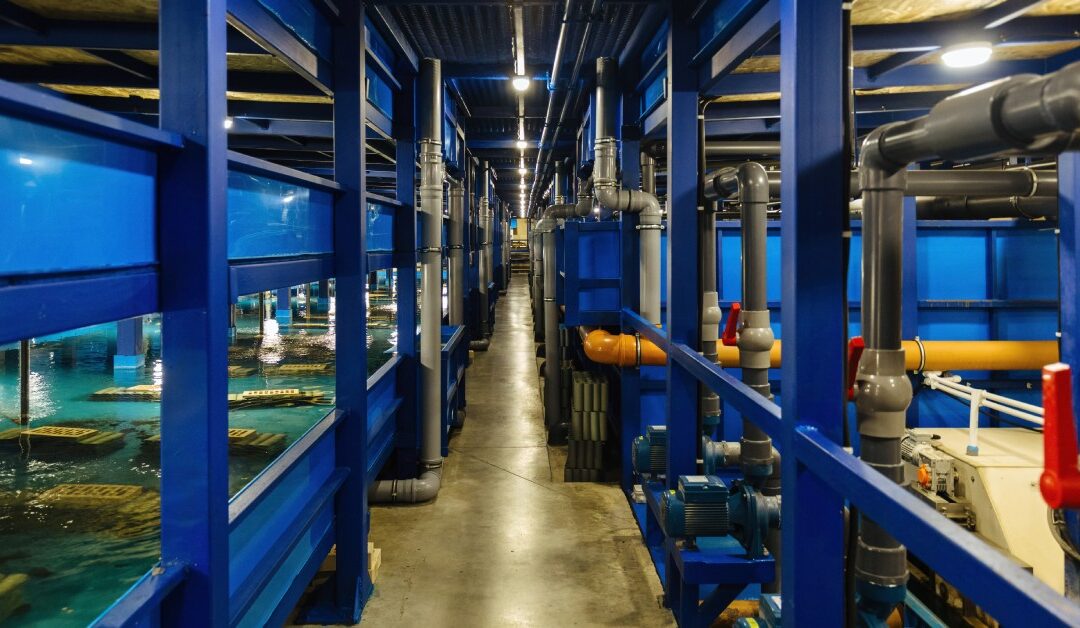

Pyridine may not be a recognizable material to everyday consumers, but it plays a crucial role in many industrial processes. Understanding how pyridine is produced is critical for industrial manufacturers and chemical engineers who rely on this versatile compound for...

by Gordon Post | Jun 14, 2024 | Uncategorized

Zinc chloride is a versatile chemical compound that various industries utilize thanks to its unique properties. This inorganic compound, represented by the formula ZnCl₂, is highly soluble in water and exhibits hygroscopic characteristics. It plays a crucial role in...

by Gordon Post | Jun 7, 2024 | Uncategorized

The “mole” is fundamental in chemistry, yet students and prospective lab technicians often misunderstand it. Understanding the mole is crucial for anyone pursuing a career in science. We will demystify the concept of a mole, its historical context, its significance in...

by Gordon Post | Jun 4, 2024 | Uncategorized

Temperature is a critical factor in chemical science that can significantly influence chemical behaviors and properties. Understanding the four common ways temperature impacts chemicals is essential for chemical engineers, scientists, and lab technicians. This...

by Gordon Post | May 21, 2024 | Uncategorized

In industrial manufacturing, chemicals play a pivotal role in the production and refinement of many products, from everyday household items to complex machinery. Understanding the types of chemicals industrial manufacturers utilize and their applications can provide...