Your cart is currently empty!

Author: Kate Romeo

-

4 Tips for Choosing Reliable Suppliers for Lab Chemicals

Working in a laboratory or industrial setting requires using high-quality chemicals and materials. It is essential to source these products from suppliers who value quality, reliability, and safety. Keep reading to learn four tips for choosing reliable suppliers for lab chemicals so that your work remains efficient and safe.

Assess Quality Standards and Certifications

Evaluate the supplier’s certifications and commitment to quality control. Responsible suppliers should have qualifications and certifications from accredited organizations, such as ISO 9001 and other quality assurance standards relevant to their industry.

These certifications ensure products meet internationally recognized benchmarks and have undergone rigorous quality control testing. Obtaining a certificate of analysis for the requested products will provide transparency and confidence in your desired lab chemicals’ quality and consistency.

Check Experience in the Industry

Awareness of a supplier’s experience in the industry can ensure you receive quality chemicals and excellent customer service. Companies with good reputations have developed long-term relationships with their clients. Choosing a supplier with decades of experience in the industry reduces the risks associated with inexperienced companies that may not have the same level of commitment to product quality and customer satisfaction.

Preview Their Range of Products

Another essential factor to consider is a supplier’s product range. Choosing from a wide selection increases the likelihood that you will find what you need without sourcing from multiple suppliers, which can be time-consuming and expensive. An excellent supplier will be able to provide an assortment of chemicals and materials for your applications, including rare and specialized chemicals.

Confirm Environmental Sustainability Efforts

Finally, consider the supplier’s commitment to environmental sustainability. Suppliers that follow eco-friendly practices demonstrate a commitment to ethical operations. Sustainability efforts include safe chemical disposal, low-impact manufacturing processes, and reduced energy consumption. By choosing suppliers with these sustainability initiatives, you contribute to the preservation of our environment and partner with professionals dedicated to the quality and integrity of their products.

By following these tips for choosing reliable suppliers for lab chemicals, you can receive high-quality and dependable materials necessary for your work. These factors will help you establish the best possible relationship with a supplier. If you’re looking for a place to buy lab chemicals online, look no further than Post Apple Scientific. We check all the boxes when it comes to responsibly sourcing chemicals for your business.

-

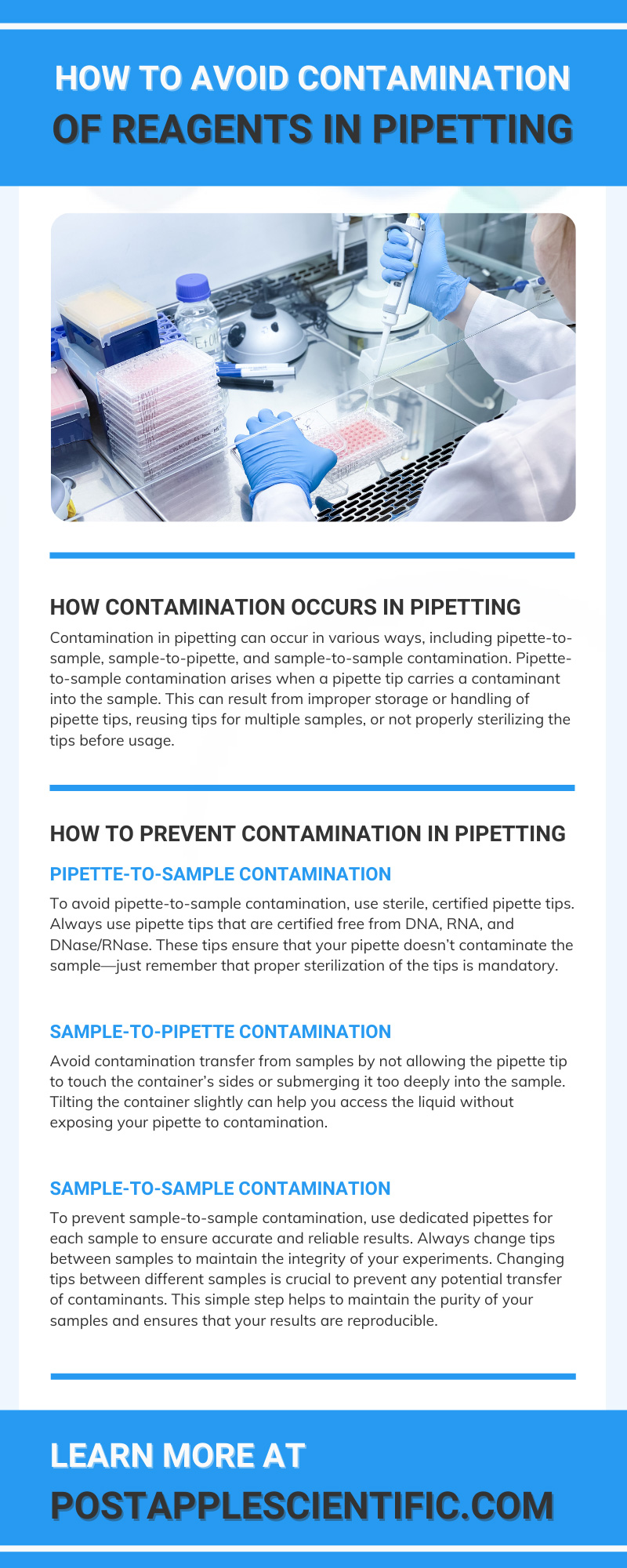

How To Avoid Contamination of Reagents in Pipetting

When working in manufacturing facilities, laboratory spaces, school labs, or research labs, understanding how to avoid contaminating reagents in pipetting is essential. Contamination is not only inconvenient but can also lead to inaccurate results and wasted resources. Keep reading to learn more about common contamination occurrences and how to avoid them in your laboratory.

How Contamination Occurs in Pipetting

Contamination in pipetting can occur in various ways, including pipette-to-sample, sample-to-pipette, and sample-to-sample contamination. Pipette-to-sample contamination arises when a pipette tip carries a contaminant into the sample. This can result from improper storage or handling of pipette tips, reusing tips for multiple samples, or not properly sterilizing the tips before usage.

Sample-to-pipette contamination happens when the sample contaminates the pipette, usually due to aerosol contamination or touching the sides or bottom of the container while pipetting. The contaminated pipette can then transfer the contaminant to other sample wells.

Sample-to-sample contamination is the cross-contamination between different samples, usually caused by the reuse of pipette tips or accidental movement of droplets by creating aerosols while over-pipetting or when releasing the plunger too quickly.

The Importance of Preventing Contamination

Contamination of reagents in pipetting can lead to inaccurate and unreliable testing results, which wastes valuable resources and requires time-consuming troubleshooting. In extreme cases, it can even result in the loss of entire studies, jeopardizing the research process as a whole. However, by implementing proper pipetting techniques and adopting preventative measures, such as using filtered tips and working in a clean environment, you can significantly reduce these risks. This helps maintain the integrity of your research and ensures that you obtain accurate and reliable results, enabling you to make confident conclusions and advancements in your field.

How To Prevent Contamination in Pipetting

Now that you understand the potential avenues for contamination, you can gain an understanding of how to avoid contamination of reagents in pipetting and keep your workspace clean.

Pipette-to-Sample Contamination

To avoid pipette-to-sample contamination, use sterile, certified pipette tips. Always use pipette tips that are certified free from DNA, RNA, and DNase/RNase. These tips ensure that your pipette doesn’t contaminate the sample—just remember that proper sterilization of the tips is mandatory.

You must also implement proper storage and handling techniques. Keep your pipette tips in proper storage conditions; sealed tip boxes and racks help protect tips from environmental contaminants. Always use gloves while handling tips, and avoid touching the pipette tips with your hands.

Finally, be sure to change tips between samples to prevent cross-contamination. Even if the sample content seems similar, using fresh tips each time ensures the purity of your samples.

Sample-to-Pipette Contamination

Avoid contamination transfer from samples by not allowing the pipette tip to touch the container’s sides or submerging it too deeply into the sample. Tilting the container slightly can help you access the liquid without exposing your pipette to contamination.

Use careful movements and techniques to avoid unwanted contact. Use an anti-droplet pipetting technique by gently touching the pipette tip to the container wall, allowing the liquid to flow smoothly into the pipette tip without splashing.

Sample-to-Sample Contamination

To prevent sample-to-sample contamination, use dedicated pipettes for each sample to ensure accurate and reliable results. Always change tips between samples to maintain the integrity of your experiments. Changing tips between different samples is crucial to prevent any potential transfer of contaminants. This simple step helps to maintain the purity of your samples and ensures that your results are reproducible.

Consider using barrier tips as an additional precautionary measure. Barrier tips create a physical barrier between your sample and the pipette, providing an extra layer of protection against cross-contamination. They are particularly beneficial when working with hazardous or sensitive samples, as they minimize the risk of unwanted interactions and maintain the integrity of your experiments.

Implementing Lab Practices To Prevent Contamination

In addition to mastering proper pipetting techniques, it is crucial to adopt and implement good laboratory practices to maintain the integrity of your reagents and samples, keeping them free from contamination. Regular equipment maintenance is a vital procedure that includes conducting regular maintenance on all laboratory equipment. This is not limited to pipettes alone, and this process plays a pivotal role in preventing the spread of contaminants. By adhering to scheduled maintenance routines, you can ensure that the equipment functions optimally and minimize the risk of cross-contamination.

Proper storage of reagents and samples is of the utmost importance to prevent contamination from the environment or other samples. By storing reagents in their respective designated areas, following specified temperature requirements, and implementing proper labeling protocols, you can safeguard the integrity of your materials and reduce the likelihood of cross-contamination.

Also, ensuring all laboratory personnel receive comprehensive and ongoing training in proper pipetting techniques and contamination prevention is essential. By equipping your team with the knowledge and skills needed to handle pipettes correctly and to implement effective contamination prevention strategies, you can maintain the highest standards of quality and accuracy in your laboratory operations.

By emphasizing the significance of these practices and integrating them into your laboratory routine, you can enhance the reliability of your results and contribute to a contamination-free working environment.

Where To Find Materials for Training

If you’re looking for ways to implement anti-contamination techniques in your facility, you’ll need equipment and reagents to work with. When you need lab supplies and equipment, look no further than Post Apple Scientific. As a reputable lab reagents supplier, we provide the solutions your lab requires for high-quality training and experiments. We also offer pipettes and other equipment necessary for conducting anti-contamination training.

Maintaining the purity of reagents during pipetting is critical for reliable and accurate experimental results. By understanding the ways contamination can occur and implementing proper pipetting techniques and good laboratory practices, you can significantly reduce the risk of reagent contamination. Precision and attention to detail in your work can make a significant difference in the success of your scientific endeavors—remember to visit Post Apple Scientific for all of your facility’s lab equipment requirements and training supply needs.

-

4 Must-Have Lab Equipment for Medical Facilities

Medical facilities are the backbone of our healthcare system. They play a crucial role in diagnosing, treating, and preventing diseases. To ensure that these facilities function optimally, they must have the proper tools and equipment. Keep reading to discover the must-have lab equipment for medical facilities. Investing in high-quality equipment guarantees accurate and reliable results and promotes the longevity and success of the medical facility.

Microscopes

A fundamental piece of equipment in any medical lab is the microscope. These devices come in various models and help technicians examine bacteria, cells, tissues, and other microscopic samples. In medical facilities, microscopes help clinicians and researchers identify pathogens, study cellular structures, and diagnose diseases. Aside from medical diagnosis, these devices also play a vital role in research. Microscopes guide the development of new treatments and preventive measures.

Centrifuges

Centrifuges are essential in separating different components within a liquid sample, such as blood, urine, or other solutions. By spinning the sample at high speeds, centrifuges generate a strong centrifugal force that separates particles based on their size and density. This separation process is crucial in medical tests and analyses like DNA isolation, blood typing, and determining the concentration of specific biomolecules. Centrifuges come in assorted sizes and types, each designed to serve particular needs within a medical facility.

Autoclaves

In medical facilities, sanitization and sterilization are critical in preventing contamination and ensuring the safety of patients and personnel. Autoclaves are the standard tool for achieving these goals. These devices use pressurized steam to sterilize medical instruments, labware, and waste materials. When operated correctly, autoclaves effectively eliminate microbes and spores, reducing the risk of hospital-acquired infections and ensuring the reliability of lab results.

Chemicals and Solutions

Various chemicals and solutions are indispensable in a medical facility, as they are used for sample preparation and other laboratory procedures. Examples include buffer solutions to maintain pH, stains to visualize cellular components, and solutions for growing bacteria or cell cultures. Laboratories must not only possess an adequate supply of the necessary chemicals but also maintain proper storage conditions and handling procedures for safety and efficiency. Finding a scientific chemical company like Post Apple Scientific will help ensure your lab stays stocked with the chemicals and solutions it needs.

Investing in must-have lab equipment for medical facilities ensures the accuracy and efficiency of diagnostic and research procedures. It is also important to continually maintain and service these devices to guarantee optimal performance and longevity. By equipping medical facilities with these essential tools, healthcare professionals can better fulfill their roles in promoting public health and improving the overall quality of healthcare.

-

Why Oxalic Acid Is Often Used as a Cleaning Agent

Have you ever heard of oxalic acid? It may be an ingredient in some of your go-to cleaning solutions and detergents. It has various chemical properties and a wide range of cleaning applications. Keep reading to learn more about oxalic acid and why it is often used as a cleaning agent.

Ability to Remove Stains

Oxalic acid is a common cleaning agent because of its stain-fighting abilities. Oxalic acid is incredibly effective at removing stains while preserving the base material. It is ideal for removing marks, stains, and rust from various surfaces. For example, oxalic acid can eat away at the rust on metal pipes, appliances, and other surfaces. Because it has similar properties to bleach, you can find it in a variety of cleaners and laundry detergents.

Use oxalic acid cautiously. In high concentrations, this substance can cause corrosive damage on some surfaces.

Sterilizing Industrial Equipment

Oxalic acid has a variety of commercial and household applications as a cleaning agent and detergent. It is also useful in industrial applications to sterilize heavy equipment. It can remove rust from metallic equipment and aid mineral processing mechanisms. As a detergent, it also has applications in cleaning and bleaching fabric in large-scale textile applications.

Emerging Uses in Medical Sterilization

You can use oxalic acid to clean and sterilize medical instruments. It even has uses in purifying and diluting certain chemicals. As a cleaning product, it can purify solutions and surfaces for medical experiments. However, this acid can negatively affect the body, which reduces its medical applications. Still, scientists are testing more medical applications of oxalic acid due to its effects.

Now that you know several applications of oxalic acid, you may be interested in using it in your own workplace. You can buy oxalic acid at Post Apple Scientific! We offer a wide range of chemicals and solvents for cleaning purposes and more. Browse our website today to find all the solutions you need.

-

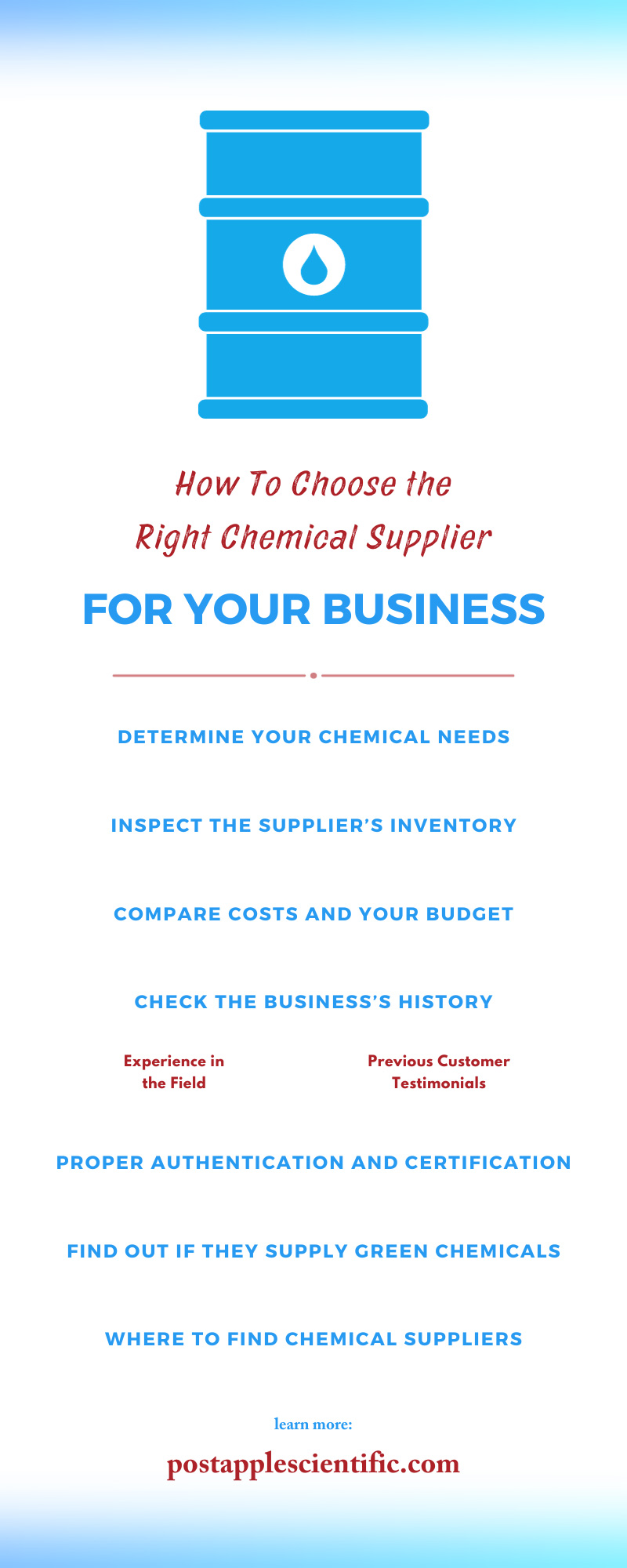

How To Choose the Right Chemical Supplier for Your Business

Are you looking for a chemical supplier for your laboratory, manufacturing facility, or other type of business? If so, you may find it difficult to choose one company to work with out of the numerous in the chemical supply industry. Instead of choosing at random, follow this guide to select the right company that meets your business’s needs. Keep reading to learn how to choose the right chemical supplier for your business.

Determine Your Chemical Needs

The first thing to do before you start looking for a chemical supplier is to determine which materials you need. If you’re choosing a supplier for a new laboratory or other facility, consider which chemicals you’ll need to conduct experiments, manufacture, clean, and perform other tasks. Don’t forget to factor the quantity of these chemicals into your calculations as well. No scientist or manufacturer wants to run out of materials midway through a project. These calculations will give you a suitable starting point and allow you to start looking for suppliers that offer your needed products.

Inspect the Supplier’s Inventory

Once you’ve determined your business’s chemical needs, you should take a closer look at the suppliers you are considering. Compare your chemical list with the supplier’s website to find out if they can supply the chemicals, solutions, and solvents your business will require regularly. This is especially important when it comes to inspecting cleaning supplies and sterilization materials because your lab or other facility will need a steady supply of these to maintain a safe working environment.

You may also want to investigate your potential supplier’s shipment and ordering options. Do they offer bulk shipments to fulfill large chemical needs? Bulk shipments can help you keep frequently used products in stock when you need them most.

Compare Costs and Your Budget

Even if a supplier offers all the chemicals you could ever need, they won’t be of any use if everything exceeds your business’s budget. Before shopping around for a chemical provider, make sure you set a budget for chemical supplies that your business can afford. Because these supplies are crucial to your daily cleaning routines, experiments, manufacturing, and any other applications, you want to invest an appropriate amount of your funding. Once you have that set, compare your budget with the supplier’s offers. Again, check to see if they offer bulk orders. Bulk chemical purchases can help you save money on orders and shipping costs by reducing the cost per product.

Check the Business’s History

Whether you’re ordering from a solvent provider or any other type of supplier, it’s crucial that you take the time to investigate the company before investing. You can check multiple aspects of a business’s history through its website, social media pages, online reviews, and customer service team. Below are a few aspects of a business’s history to look out for.

Experience in the Field

One factor that contributes to a company’s trustworthiness and quality is its experience in the field. Having many years of experience selling chemicals and solvents allows a company to establish customer trust and navigate the industry. They will have more experience working through shipping or supply errors and know how to address any questions or concerns you might have. Having more experience also allows companies to better recommend products for your business to provide exactly what you need. More experienced companies will stay up to date on trends and changes within the industry to help you get the latest advancements in chemicals and solvents. And while new businesses with less experience can still be trustworthy, you’ll need to explore other factors than experience alone to tell.

Previous Customer Testimonials

Another way you can explore a company’s history is by investigating its customer reviews and testimonials. A business’s relationship with its customers can tell you a lot about its trustworthiness. Browsing customer reviews also helps you learn more about the business and how they treat their customers. Check the supplier’s website or listings on the web for customer reviews. You could also consider asking their customer service team if they can point you toward any testimonials from previous customers. You can even find information through comments on the supplier’s social media. Don’t forget to look over both the positive and negative comments to learn more about the business and its successes and struggles.

Proper Authentication and Certification

Another key factor to consider when choosing a chemical supplier is whether they have the proper certifications. Working with dangerous chemicals and solvents requires authentication and certification on the supply and business end, especially when buying and selling these materials. Browse the company site or ask customer service representatives if they can present up-to-date certifications, such as following ISO certifications and OSHA standards. This helps ensure you’re working with an authentic, legal chemical supplier.

Find Out if They Supply Green Chemicals

The chemical industry is constantly changing and adapting, and part of the adaptation process requires addressing environmental impact. Some chemicals can be harmful to the environment, so it’s crucial that a supply company uses safe and responsible storage and transportation methods for these materials. You may even want to search for suppliers that offer green chemicals, which are produced in more eco-friendly ways and offset the use of fossil fuels. Companies that offer bulk shipping can also help reduce emissions by transporting more materials in fewer shipments.

Where To Find Chemical Suppliers

Now that you know the considerations to make and features to look out for in a supply company, you might be wondering where to start. Fortunately, you don’t need to look far to find a trustworthy supplier that checks these boxes. Post Apple Scientific is a scientific and chemical supply company that prioritizes our customers. Not only do we offer a wide range of products, including hundreds of chemicals and solvents, but we also offer convenient buying options such as bulk ordering. We carry common lab supply chemicals and solvents, including bulk hydrochloric acid and more. Browse our website at Post Apple Scientific to learn more and see our full range of products.

After exploring this guide on how to choose the right chemical supplier for your business, you have all the tools you need to select a trustworthy company to work with. If you’re looking for a company that meets these criteria and more, don’t forget to browse Post Apple Scientific’s wide selection of chemicals and solvents today.

-

How Zinc Chloride Is Used in Food Production

Have you ever wondered about the applications and uses of certain chemical compounds? Zinc chloride is a chemical material that has a wide range of applications and shows up in many resources we use daily, namely food products. Keep reading to learn how zinc chloride is used in food production.

What Is Zinc Chloride?

Zinc chloride is an inorganic chemical compound. It often appears in a white or colorless crystalline form and is solid at room temperature. Because it is crystalline, it is highly soluble in water. While forms of this chemical compound can be useful for disinfecting and cleaning, the food processing industry also uses it in various ways.

How Is Zinc Chloride Used in Food Production?

Food processing plants use zinc chloride in a range of applications. Food companies mainly use this chemical compound as a preservative, although they also use it when making processed products. Some common processed products in which you can find zinc chloride include breakfast cereals, snack bars, and even cheese. This product is also common in baked goods, including muffins and bread. Zinc chloride reduces the deterioration of yeast in baked goods, which causes unsightly white spotting. It has many more uses, including extracting sugar from molasses, emulsifying sweets like chocolate, and coloring food products.

Benefits of Using Zinc Chloride

Because many food processing companies use zinc chloride as a preservative, it helps extend the shelf life of many foods. You can often find this chemical compound in products, such as canned tuna and other canned meat products, to prevent spoilage. Zinc chloride also protects the consistency of foods, such as ice cream, contributing to its shelf life and quality.

These are just a few of the many ways zinc chloride is used in food production. If you’re experimenting with food production or own a food processing plant, you may need a steady source of chemical compounds such as zinc chloride. Fortunately, you can find zinc chloride for sale here at Post Apple Scientific. We offer a wide range of products that aid food processing and other applications.

-

The Difference Between Reactants and Reagents

Many people training in the laboratory industry can accidentally use the terms reactant and reagent interchangeably. This is because they are both involved in the chemical reaction process. However, some key differences exist between these terms that you should know. Keep reading to learn the difference between reactants and reagents in the laboratory space.

What Are Reactants?

In chemical experiments, reactants are the materials you start with that undergo change during a chemical reaction. A key point to remember is that the chemical reaction consumes the reactants. Reactants can have a solid, liquid, or gaseous phase and may change during the reaction. When drawing a chemical equation, reactants are the substances or materials to the left of the arrow. Reactants lead to the chemical reaction that results in chemical products. Two common reactants in a chemical equation we all know are hydrogen gas and oxygen gas, which form liquid water.

What Are Reagents?

Reagents are also part of chemical reactions. Reagents are the substances or compounds that scientists use to facilitate a reaction. Scientists may also use reagents to test whether a chemical reaction occurs at all. They also use reagents to test the presence or absence of chemicals in substances or mixtures based on the chemical reaction that does or doesn’t take place. The reagent binds to the present substance and forms a reaction. Reagents may or may not be consumed during this process. Like reactants, reagents can take solid, liquid, or gaseous phases before a reaction.

The Differences Between Reactants and Reagents

The main difference between reactants and reagents is their roles in a chemical reaction. Unlike reactants, which are your starting materials in a chemical equation, reagents are the substances you add to those starting materials. Also, chemical reactions may not always consume reagents; they will, however, consume reactants.

Ultimately, both reactants and reagents are crucial in a chemistry laboratory for many experiments, tests, and other applications. Now that you know the main difference between reactants and reagents, you can better understand your laboratory materials. This is an important distinction to teach students in your laboratory and any lab technicians training in chemical reactions. And if you’re looking for common chemical reactants for your laboratory, you can buy pyridine and other reaction solvents at Post Apple Scientific.

-

How Ethyl Alcohol Is Used in the Cosmetic Industry

Have you ever wondered why certain types of alcohol fall under the list of ingredients in some cosmetics products? For example, ethyl alcohol offers many benefits to manufacturers and beauty products. Keep reading to learn how cosmetic companies and the industry use ethyl alcohol in their products.

Cleaning Properties in Skincare

Ethyl alcohol acts as an astringent that cleans the skin, which is why it is an ideal ingredient for many skincare products, including cleansers. Ethyl alcohol promotes clean skin by killing microorganisms that could be lurking on the skin’s surface. Common microorganisms that impact skin health include fungi, bacteria, and viruses. However, ethyl alcohols in cosmetic cleansers and other products target these microorganisms to promote clean, healthy skin.

Adhering Properties Promote Long-Lasting Makeup

Adhering properties are particularly important for makeup and skincare formulations, which many consumers wear daily and expect to last all day. High-quality makeup products last longer on the skin and support all-day wear. Ethyl alcohol helps with the adhesion process, promoting longer-lasting makeup that looks better on the user. Its adhesion properties also apply to hairspray, helping the material adhere to the hair and provide a long-lasting bond.

Prevents Formula Separation

Another benefit of using ethyl alcohol in cosmetic formulations is that it promotes the adhesion of ingredients and prevents formulas from separating. This anti-separation helps products look better on shelves and apply more effectively on the skin. Product separation can cause some products to lose their effectiveness, so it reduces inventory waste.

Benefits of Ethyl Alcohol in the Cosmetic Industry

Most alcohol ingredients in cosmetics are in the formulation for the benefit of the product and the consumer. As previously mentioned, ethyl alcohol improves shelf life and product performance. It is also sustainable and non-ecotoxic. While some consumers worry about the irritating effects of alcohol in cosmetics, the fact is that most companies use it in safe and effective quantities that avoid causing skin irritation.

Above are some of the benefits of ethyl alcohol and how the cosmetics industry uses it as an ingredient. You can find ethyl alcohol for sale at Post Apple Scientific if you’re interested in using this solution for your cosmetic formulations. We supply a variety of solutions, solvents, and more to a wide range of industries, including cosmetic manufacturing.

-

3 Reasons To Buy Chemicals and Solvents in Bulk

Many professionals can take advantage of buying products in bulk. Even laboratory and processing businesses can take advantage of ordering in bulk! However, business owners and managers may be hesitant or unaware of the benefits of this practice. If you’re on the fence about this type of ordering, learn three reasons to buy chemicals and solvents in bulk.

Cost Savings

One of the biggest benefits of ordering products in bulk is the potential to save on product and shipping costs. Most bulk manufacturers provide businesses with a discount for buying a certain number of products. Businesses can further save on costs because they’re only paying for one shipment rather than reoccurring shipments with a smaller quantity of goods. If you’re looking for smart ways to stretch your business’s budget, consider investing in bulk solvents, chemicals, and cleaning supplies.

Flexibility and Stocked Inventory

Having a larger quantity of products on hand allows for greater flexibility with your applications. You don’t have to be so frugal with your materials when you have a bulk supply in storage. Many manufacturing and shipping services experience material and staffing shortages, which can lead to delays in deliveries. Ordering your chemicals and solvents in bulk ensures your inventory is stocked. This reduces downtime and keeps your lab running smoothly.

Sustainability Benefits for Businesses

Many modern businesses are concerned with sustainability. No matter your business, you may be looking for ways to become more environmentally friendly. Securing your chemicals and solvents through a bulk supplier can reduce your business’s carbon footprint and costs in one go. By opting for fewer shipments and choosing bulk shipping options, you can reduce your environmental impact. Additionally, bulk packaging produces less waste than non-bulk options.

These are the three biggest reasons why your business should buy chemicals and solvents in bulk. If you’re interested in reaping these benefits for your business, consider browsing our selection of products at Post Apple Scientific. We offer everything from chemicals and acids to food-grade caffeine powder for a variety of applications. Learn more about our bulk options today.

-

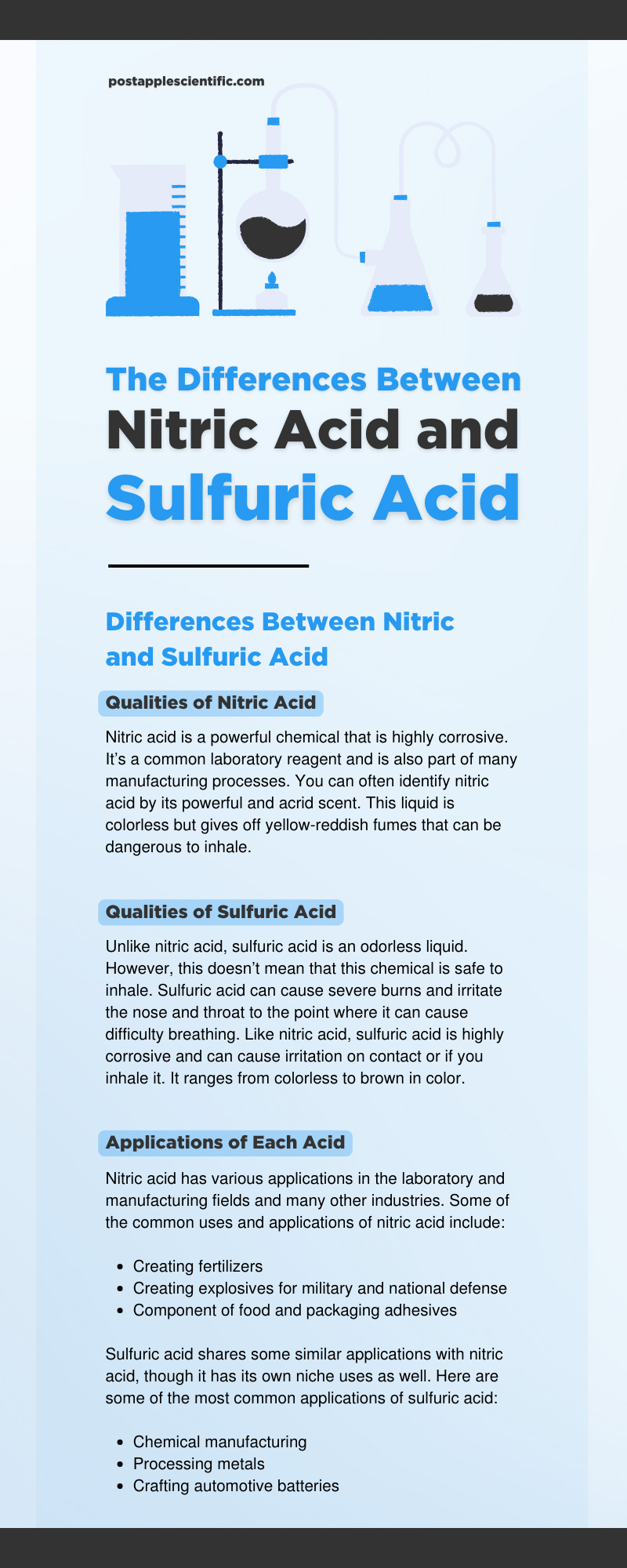

The Differences Between Nitric Acid and Sulfuric Acid

Nitric and sulfuric acids are both corrosive materials that have many similar qualities and applications. However, these chemicals also have their own unique conditions in many fields. If you’re interested in nitric or sulfuric acids for your laboratory or manufacturing business, you’ll want to know more about each. Keep reading to learn some of the similarities and differences between nitric and sulfuric acid. You can also learn more about their unique applications and why you may want to invest in these chemicals for your business.

Differences Between Nitric and Sulfuric Acid

Before you purchase chemicals for your laboratory or manufacturing needs, you must know the differences between the materials you’re working with. For example, nitric and sulfuric acid are similar chemicals with similar applications, so you need to be careful not to confuse them. Both acids can be extremely dangerous, so getting them confused or handling them incorrectly could have disastrous consequences. Keep reading to learn more about each type of chemical and the differences you should know.

Qualities of Nitric Acid

Nitric acid is a powerful chemical that is highly corrosive. It’s a common laboratory reagent and is also part of many manufacturing processes. You can often identify nitric acid by its powerful and acrid scent. This liquid is colorless but gives off yellow-reddish fumes that can be dangerous to inhale. Because of its fumes and high corrosiveness, laboratory workers and manufacturers must handle it with extreme care—exposure to this chemical can cause conditions ranging from eye and skin irritation to harmful breathing conditions.

Qualities of Sulfuric Acid

Unlike nitric acid, sulfuric acid is an odorless liquid. However, this doesn’t mean that this chemical is safe to inhale. Sulfuric acid can cause severe burns and irritate the nose and throat to the point where it can cause difficulty breathing. Like nitric acid, sulfuric acid is highly corrosive and can cause irritation on contact or if you inhale it. It ranges from colorless to brown in color. Additionally, it requires careful storage in the laboratory and manufacturing spaces because it can produce hazardous and flammable gases that can cause explosions.

Applications of Each Acid

Nitric acid has various applications in the laboratory and manufacturing fields and many other industries. Some of the common uses and applications of nitric acid include:

- Creating fertilizers

- Creating explosives for military and national defense

- Component of food and packaging adhesives

- Purifies metals

- Processes dyes in manufacturing

- Coats furniture

- Critical cleaning agent and pH buffer in laboratories

Sulfuric acid shares some similar applications with nitric acid, though it has its own niche uses as well. Here are some of the most common applications of sulfuric acid:

- Chemical manufacturing

- Processing metals

- Crafting automotive batteries

- Cleaning agent for drain un-blockers, detergents, and chemical sprays

- Creates agricultural fertilizer

As you can see, the corrosive nature of both acids leads them to some similar applications. However, both have unique uses as well, especially in the manufacturing and laboratory studies industries. No matter how you use them, you must handle both nitric and sulfuric acid with care due to their corrosive and hazardous qualities.

Storage and Handling of Each Acid

If you work in laboratory studies or manufacturing, you may already know the careful practices that using these chemicals requires. If you’re not already familiar with the right procedures or you need a safety refresher, here are some tips for handling these dangerous chemicals.

Sulfuric acid is more corrosive than nitric acid, making it more dangerous to handle and transport. Note that PPE is necessary for handling both acids. PPE is extremely important when using nitric and sulfuric acid due to the hazardous nature of both chemicals. When working with either chemical, you must have a controlled environment, such as a fume hood. Corrosion-resistant fume hoods are useful for laboratory testing processes because of the corrosive nature of both chemicals.

You should always use protective eyewear, such as safety goggles or glasses, to protect yourself from eye irritation or chemical splashes. Respirators are also necessary when using both nitric and sulfuric acid. You should always use a respirator mask and work in a well-ventilated area with these chemicals to prevent airway irritation.

When storing nitric and sulfuric acid, label them carefully. These acids can be flammable and cause explosions, so mark them as such and store them away from any heat sources in your laboratory.

How To Distinguish Nitric and Sulfuric Acid

Because they have similar applications, nitric and sulfuric acid can seem quite similar. However, these acids have unique properties and traits to help you tell them apart. While both can be colorless, sulfuric acid can also appear browner in color.

The odor from nitric acid can help you identify the chemical. Nitric acid has an acrid smell, while sulfuric acid is odorless (though you should avoid inhaling either chemical for safety purposes). Be sure to label these chemicals so as not to confuse them during your laboratory experiments or other applications.

Which Acid Is Better for Your Lab Applications

Now that you know the differences between nitric and sulfuric acid, as well as how to handle them and tell them apart, you may be wondering which acid is best for your laboratory applications. Both can fill several laboratory roles, such as helping to calibrate instruments and equipment, cleaning equipment parts, and causing reactions. But which one will work for your laboratory?

The powerful scent of nitric acid can be more of an irritant than sulfuric acid, so keep this in mind when ordering your materials. However, nitric acid is extremely effective as a pH buffer and cleaning agent, so don’t rule it out.

Now that you know the differences between nitric and sulfuric acid, you can more accurately choose the best solutions for your laboratory or manufacturing applications. If you’re interested in learning where to buy nitric acid and other chemicals for a variety of applications, you can find high-quality solvents and solutions at Post Apple Scientific. Due to its unique conditions, nitric acid can be difficult to obtain, but our careful handling processes ensure that you receive stable, high-quality chemicals for your laboratory needs. Browse our full selection of chemicals at Post Apple Scientific today.