by admin | Nov 8, 2023 | Uncategorized

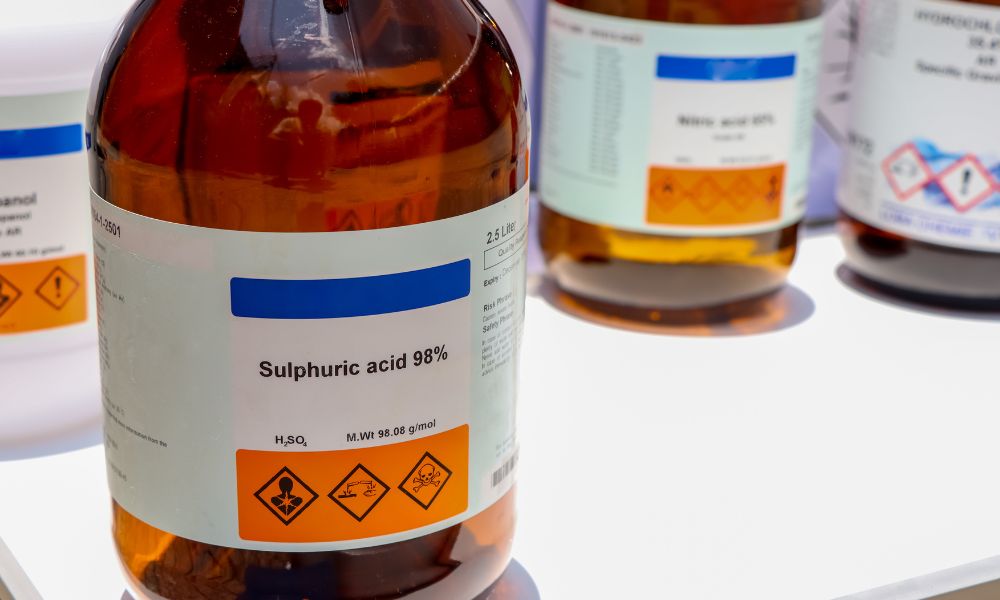

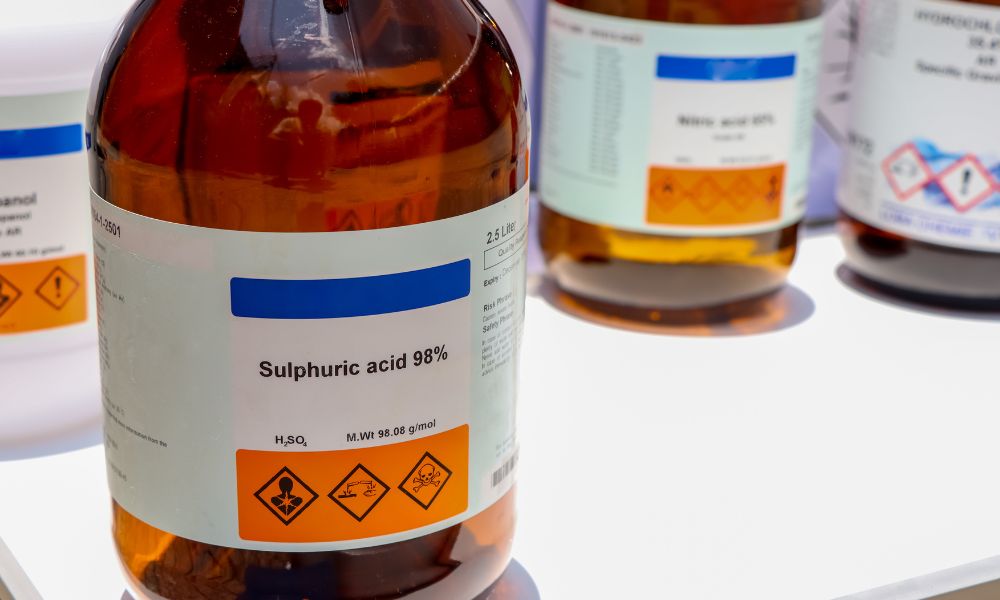

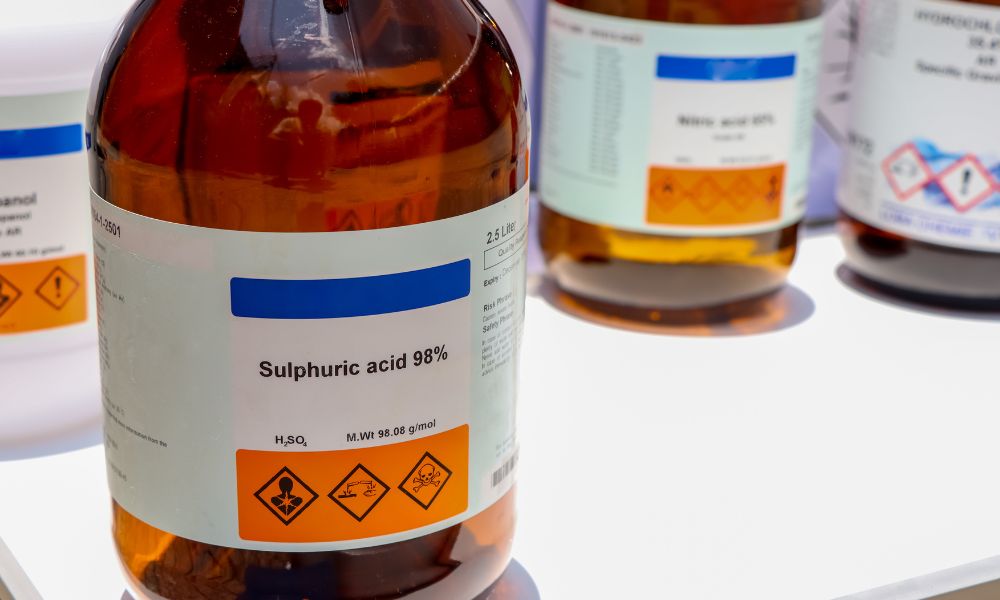

Sulfuric acid is often known for its corrosive properties, but it plays an essential role in various industrial processes. Among these applications, one of the most important is its use in water treatment. Learn more about the properties of sulfuric acid solutions and...

by admin | Oct 27, 2023 | Uncategorized

The average consumer might think of coffee, tea, and energy drinks when they think of the word “caffeine.” However, specific types of caffeine have important applications in scientific research and laboratory studies. Scientists use lab-grade caffeine as a lab reagent...

by admin | Oct 26, 2023 | Uncategorized

Understanding the role of nitric acid solutions in metal etching is crucial for metal finishing companies, foundries, and manufacturing companies. To grasp the significance of nitric acid in this process, you must first learn the basics of nitric acid and why it is so...

by admin | Oct 13, 2023 | Uncategorized

Solvents play a crucial role in many processes across various industries. A solvent is a liquid substance that can dissolve other substances, forming a solution. While their properties make them indispensable, mishandling solvents can pose significant risks....

by admin | Oct 6, 2023 | Uncategorized

Working in a laboratory or industrial setting requires using high-quality chemicals and materials. It is essential to source these products from suppliers who value quality, reliability, and safety. Keep reading to learn four tips for choosing reliable suppliers for...

by admin | Oct 5, 2023 | Uncategorized

When working in manufacturing facilities, laboratory spaces, school labs, or research labs, understanding how to avoid contaminating reagents in pipetting is essential. Contamination is not only inconvenient but can also lead to inaccurate results and wasted...